Our Services

CP Resiliency is a distributed infrastructure technology company focused on Municipalities, Universities, K-12 schools, Healthcare Facilities, and Data Centers. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to more advanced healthcare, we create technology with purpose adding real value for customers.

At CP Resiliency we work together with customers and partners to create an ecosystem that both intuitively responds to the needs of people and helps customers achieve their business goals. It helps our customers to thrive, communities to progress and supports sustainable development to protect our planet for the next generation.

Generator Maintenance

CP Resiliency highly recommends scheduled maintenance. Your standby and emergency power system requires upkeep and maintenance. Poor maintenance schedules or standards can put your facility at risk when you need power the most. A CP Resiliency scheduled maintenance program can save lives, help you avoid costly expenses, and allow you to perform your most vital functions - without interruption. CP Resiliency employs licensed electrical and mechanical engineers to ensure that your standby and emergency power system meets the most stringent standards of excellence. CP Resiliency can provide mechanical and electrical troubleshooting, diagnostics, testing, and maintenance for all makes and models.

Load Bank Testing

Load bank testing of standby gensets is a preventive maintenance practice for an emergency power supply system (EPSS). The testing is primarily meant for diesel-powered gensets. The main purpose of this testing is to help ensure the genset's reliable operation during utility power failure. If this testing is performed regularly, it can extend the genset's life. CP Resiliency has load banks on hand that will handle wet stacking, diagnostics, and troubleshooting.If your Emergency Power Supply System (EPSS) contains a diesel-powered generator your equipment may develop a condition known as "wet stacking."

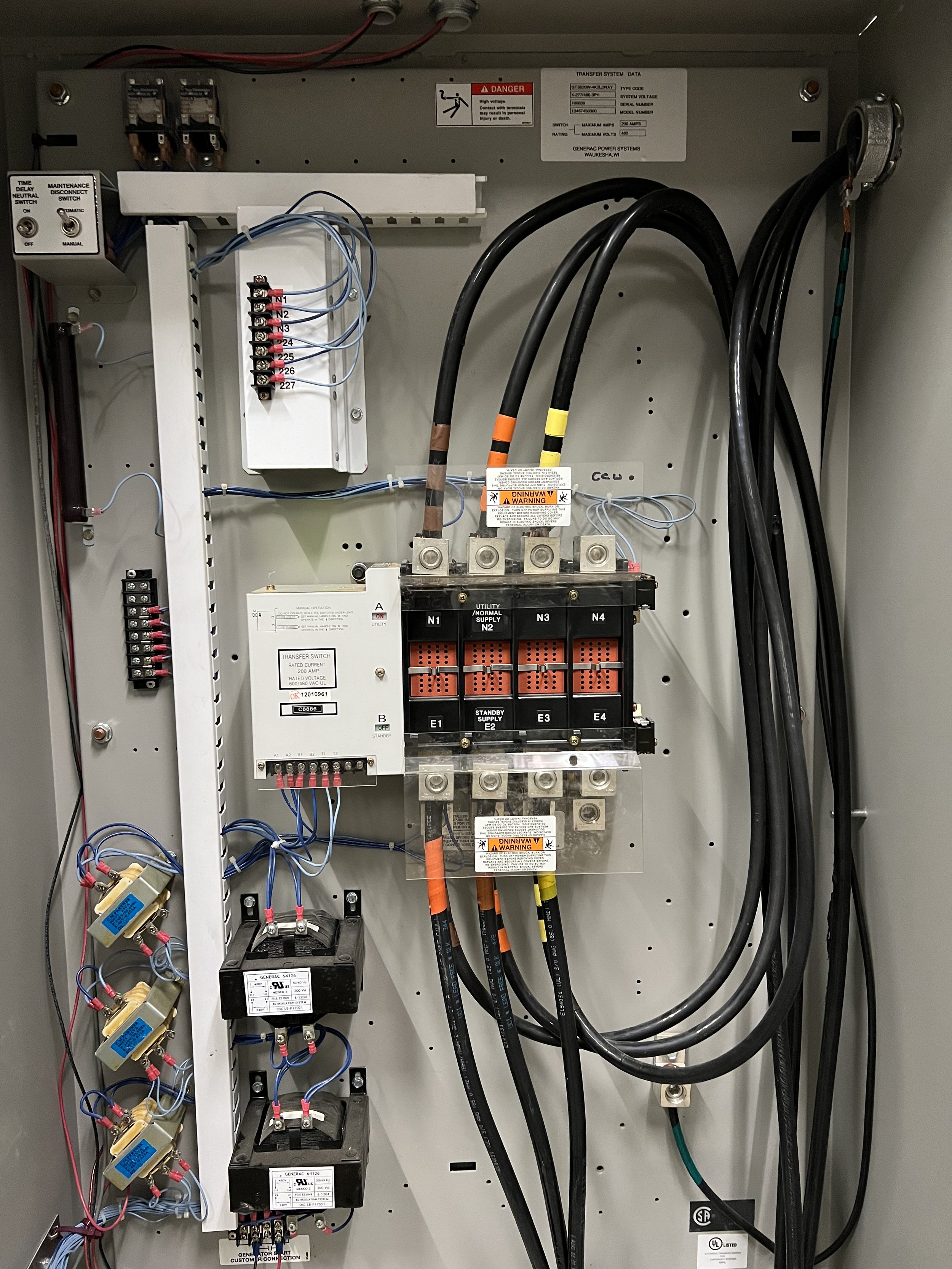

ATS Maintenance

The automatic transfer switch is vital to your emergency back-up strategy we recommend regular scheduled maintenance to ensure proper function. CP Resiliency can provide the total solution to all your needs - from automatic transfer switch installation to testing, troubleshooting and maintenance.